Fabric Grain

As a former pattern maker and garment sewer I know all too well the importance of fabric grain. If cut on the wrong grainline the fabric doesn't drape properly and the garment may fit badly depending on the design. When it comes to quilting, the rules are a little more relaxed, but they are still important.

As quilters we are mesmerized by colour when we first walk into the quilt shop...row upon row of hundreds of bolts of luscious cottons just waiting to become works of art at our hands. You may have been sewing for years, but how much do you really know about the medium you've been working with?

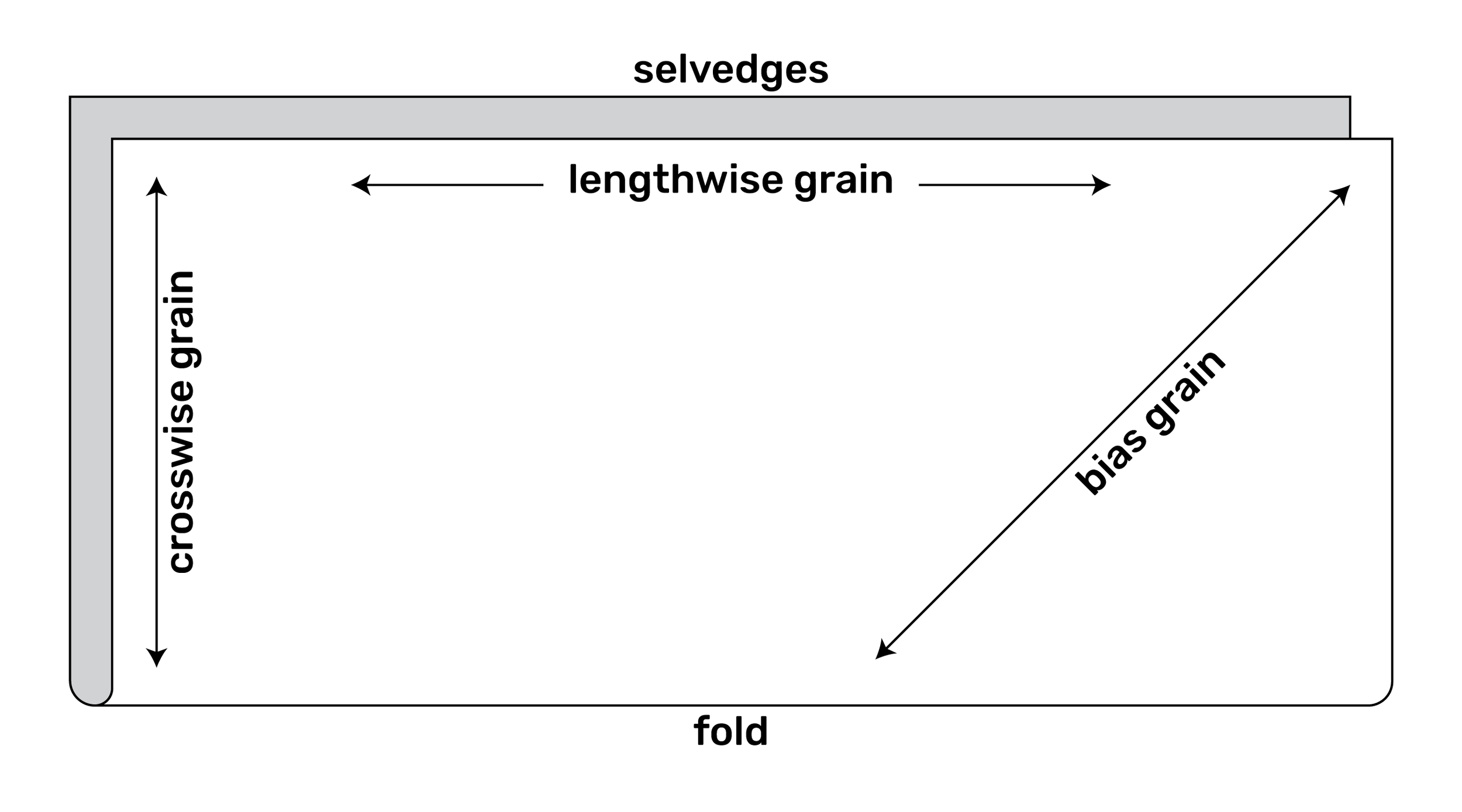

In basic terms grain refers to the direction of the threads used in the weaving process for making fabric. Straight grain, or lengthwise grain, runs parallel to the selvedge, crosswise grain runs perpendicular to the selvedge, and bias grain is at a 45° angle to the selvedge.

And now for a little more detail...

Straight grain: Also known as lengthwise grain, straight grain runs parallel to the selvedges and is the most stable direction because it has no stretch (unless it’s a knit). For those of you who make garments you are already used to laying out commercial patterns making sure that the large, dark arrows on the pattern pieces are running with the lengthwise grain. During the weaving process they are referred to as the warp threads.

Selvedges (Britain, Canada) or selvages (US): Derived from the term “self edge”, selvedges are the tightly woven outside edges of the fabric that are created during the weaving process. I personally never include selvedges when working on patchwork because the fabric is so tightly woven at the selvedge edge it may shrink more during washing and cause puckering. What the heck do I know though?! There are books on the market about using selvedges and awesome projects throughout Pinterest proving me wrong! But I still won’t include them in MY quilts…however, I might be persuaded to make a toiletry bag or tote bag from them. Refer to my post “What the heck are those circles for?” for more information about the coloured circles on selvedges.

Crosswise grain: During the weaving process crosswise grains are referred to as the weft (or woof) threads. There is a minor amount of stretch, but not enough to make things go all wonky with your quilting. As a quilter you may have seen the term WOF in a pattern or magazine which means “width of fabric”. All that means is that strips are cut from selvedge to selvedge as it comes off the bolt of fabric. The majority of my bindings for quilts are made using crosswise WOF strips.

Bias grain: Here's where the stretch comes in. Bias grain is at a 45° angle to the selvedge. For quilters the bias grain is often used for binding a quilt, most importantly for one that has curved edges. It allows the binding to more easily follow the curved edges without pulling it out of shape. Bias binding has more longevity than crosswise binding, but my personal experience with it on a quilt with straight edges is that it ripples when being applied so I prefer cutting my binding strips WOF...strictly a personal-preference-kind-of-thing. Bias is also used for hand applique when making long stems for flowers, etc. because it can be easily shaped. *** I have one important tip for quilters when sewing patches that have been cut on the bias…when at all possible put the patch with the bias edge on the bottom while sewing. The feed dogs will help ease in the fabric so it doesn’t stretch as it’s being sewn.

For garment sewers bias drapes beautifully and gives skirts and dresses that extra special something. I know I'm really showing my age here, but when I was a little girl I used to watch old black and white movies on Saturday afternoons with my grandparents...anyone else remember Fred Astaire and Ginger Rogers? Ginger's gowns were cut on the bias...that's why they flowed so beautifully while she was dancing (you young-uns can search their names online so you'll know what I'm talking about!).

*** One major tip for those of you making skirts or dresses on the bias...do not hem them until they've been on a hanger for at least 24 hours...if you don't wait your hem will be uneven. Wait 24 hours, then trim the bottom edge straight before hemming. Hanging the garment ahead of time allows the bias fabric to “settle” into place.

One thing I'd like you to do is find a piece of cotton yardage that you've purchased for one of your quilts and do the stretch test with lengthwise, crosswise and bias. This way you'll understand a little more about the properties of the fabrics you use all the time.

At a quilt store recently I was asked if I wanted my fabric cut (with scissors or rotary cutter) or torn. Gasp! I didn't even think cotton fabric was ripped anymore. I definitely prefer cutting...ripping it often pulls the lengthwise fibres and distorts the ends of the fabric usually wasting a couple of inches in the process.

I do realize that this was the norm a gazillion years ago for cotton and is still used for polyester fabrics all the time...and I do understand why it is done. Often fabric is not wound evenly on the bolt so this is a way of getting the yardage you've asked for and on grain. I'm still not impressed with what it does to the end of the fabric so I prefer to purchase a little more and straighten it myself.

Hopefully most of your questions about fabric properties have been answered. If not, let me know what burning questions you have and I'll answer them to the best of my ability. One thing we can all agree on about fabric is how much fun it is to buy it, cut it apart, and put it back together again!